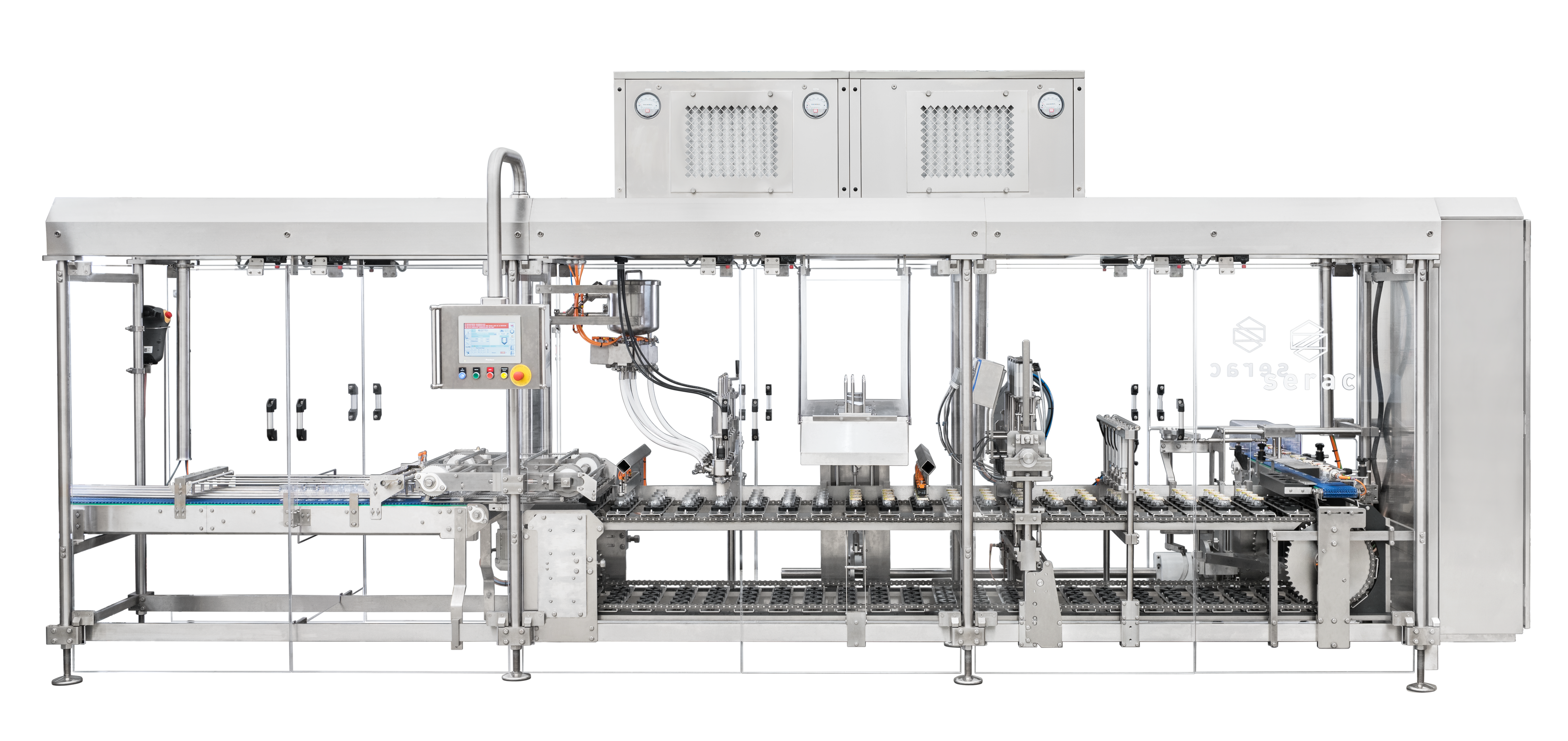

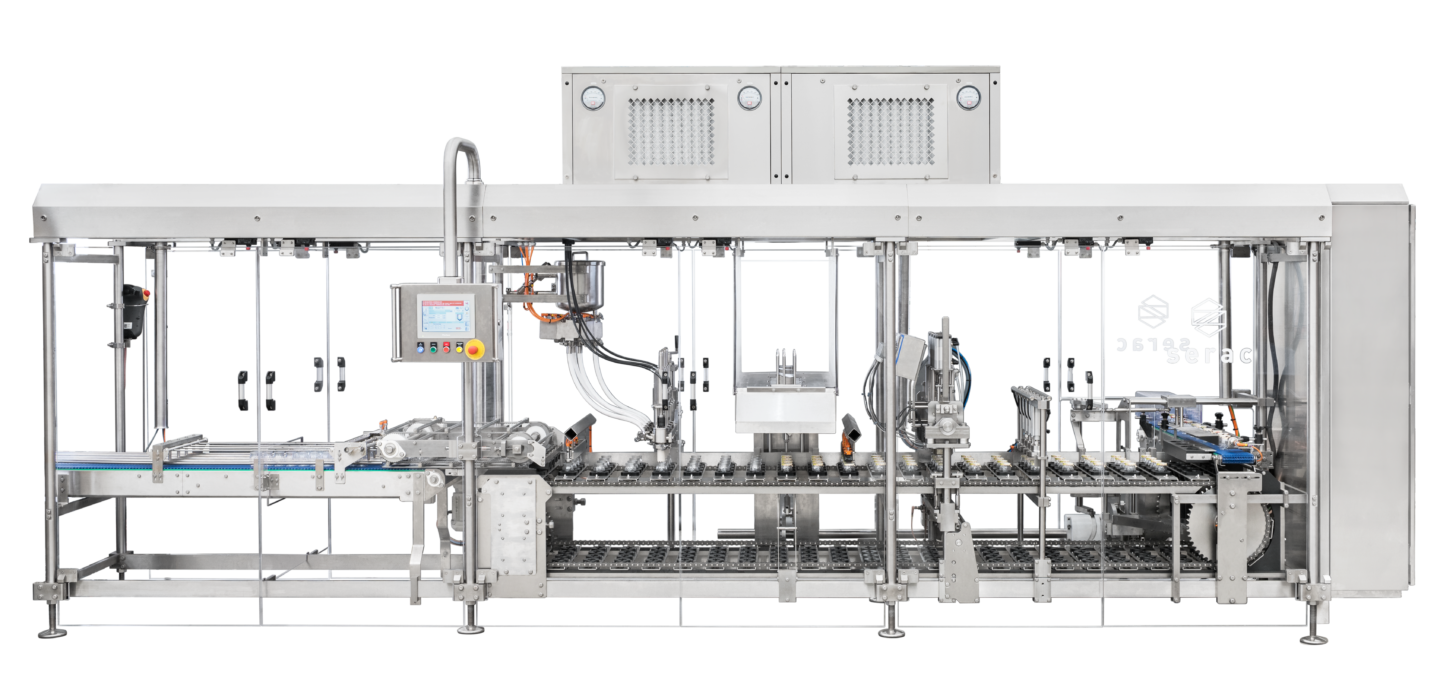

The LINEA XS is a cup filler that meets the investment constraints of medium-speed production: from 5000 to 12000 cups per hour. The LINEA XS incorporates Serac’s latest advances in terms of hygiene, ergonomics and flexibility in a refined design that makes installation and daily operation easier.

Having enticed food manufacturers in Western Europe, this new offer could also prove interesting in geographical areas where access to experienced technicians is difficult.

Uncompromising filling hygiene

The LINEA XS guarantees environmental control through a unidirectional laminar flow installed above filling operations.

It can be combined with H2O2, UV or pulsed light decontamination modules, depending on the level of bacteriological reduction required and the environmental goals aimed at. It also benefits from a new electric dosing nozzle developed by Serac, which is cleaner and more versatile.

Simplified and compact design for better TRS

The LINEA has a design that combines simplicity, efficiency and scalability. From mechanical drives or servomotors to stations that can be moved as needed, with a reduced footprint, the LINEA XS is designed to offer a flexible and a reliable production tool.

Maximum ergonomics for the operator

With a lowered chassis, storage stations within arm’s reach, and a design that provide increased visibility on the filling functions, the LINEA XS offers true working comfort to the operator in charge of running it.

Shipped ready to install

Compact, the LINEA XS can be shipped in a container without having to be dismantled and disconnected. It thus provides enhanced trust and speed upon installation, for trouble-free production start-ups, even in geographical areas where technical skills are scarce.