The new Human Machine Interface currently under development at Serac is a perfect example of what the brand stands for : « Creating performance together ». In this case, Serac worked together with packaging line operators. The OEM went to meet them in their factories in order to define, under real operating conditions, which developments would prove the most useful for their daily work.

visited plants

interviews

observation sessions

Identify the target users of the HMI

The first step in designing a solution that meets the needs of users is to identify and personify them in order to create empathy within the team that will work on the design of the HMI.

The creation of personas (fictitious users representing a target group) allows the team to remain focused on the end users. In order to build them we went to meet some users

A phase of observations and interviews

We visited three plants over four days, met with seven operator profiles and three maintenance profiles. We were able to observe machines in production, troubleshooting and cleaning. Interviews were conducted to understand the issues, needs and expectations of users during these different phases. Various profiles emerged during this research and are summarized in operator profiles.

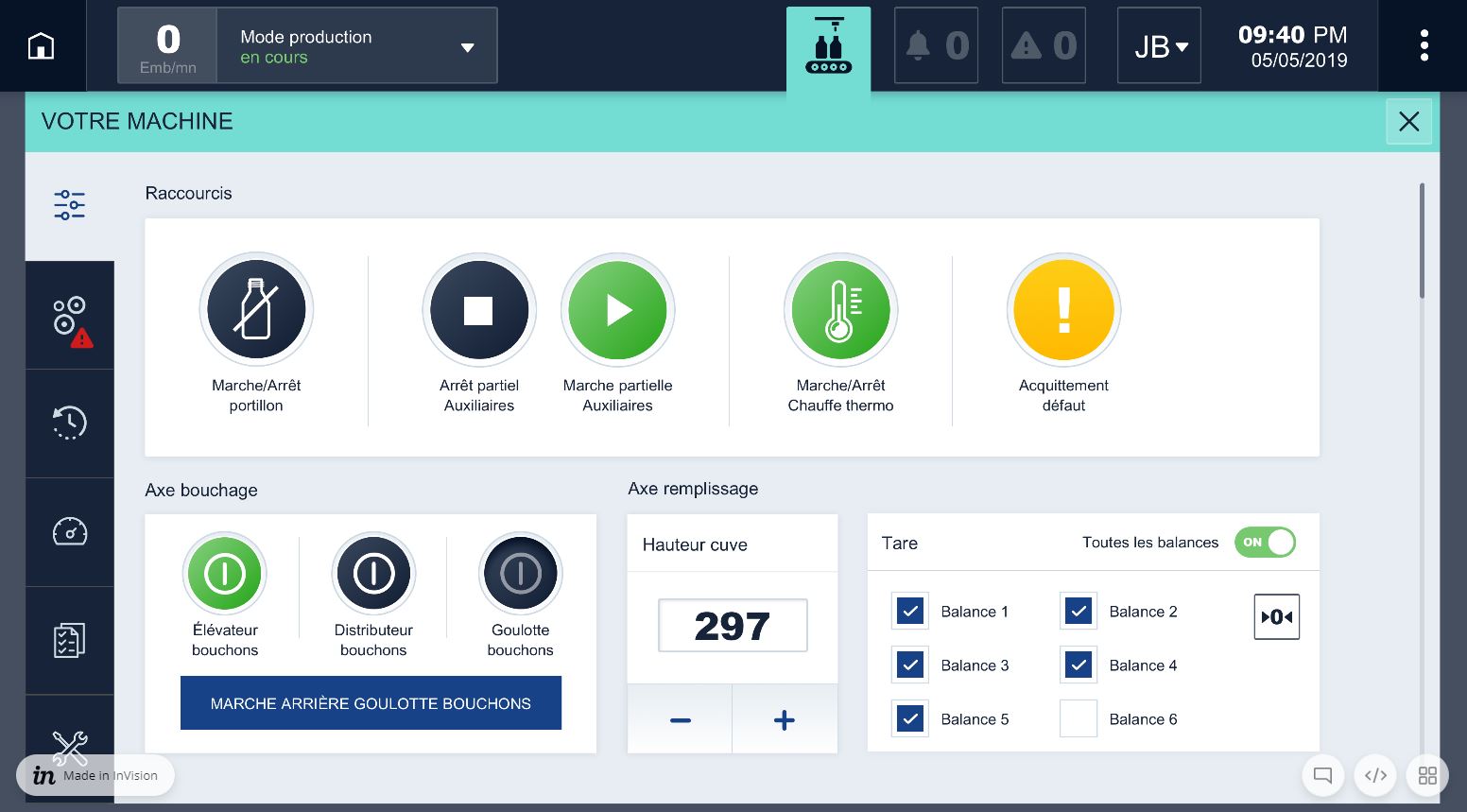

A screen of the New HMI – Production Mode

New HMI: a gateway for the connected factory.

Serac’s new HMI relies on a web-based application, developed by Orange and Serac’s teams, to offer a 100% intuitive user experience. The HMI focuses on machine operation to be as simple as possible, and features new functionalities that meet needs uncovered during the research phase. Navigation is based on several user paths, defined from hands-on feedbacks, which guide users in their daily tasks as well as in troubleshooting.

Serac’s new HMI is developed using the lastest tools from Microsoft and a software for which obsolescence management has been secured. This programming environment is widely open to new technologies and will allow, over time, to use the HMI as a gateway for the connected factory.

With this new HMI, Serac is materializing one of the keypoints of its Industry 4.0 strategy : a better support in decision-making, for expert and non-expert operators having to work with machines full of electronic components and supplying tons of data.

The first machine will be equipped with this new interface during 2021.