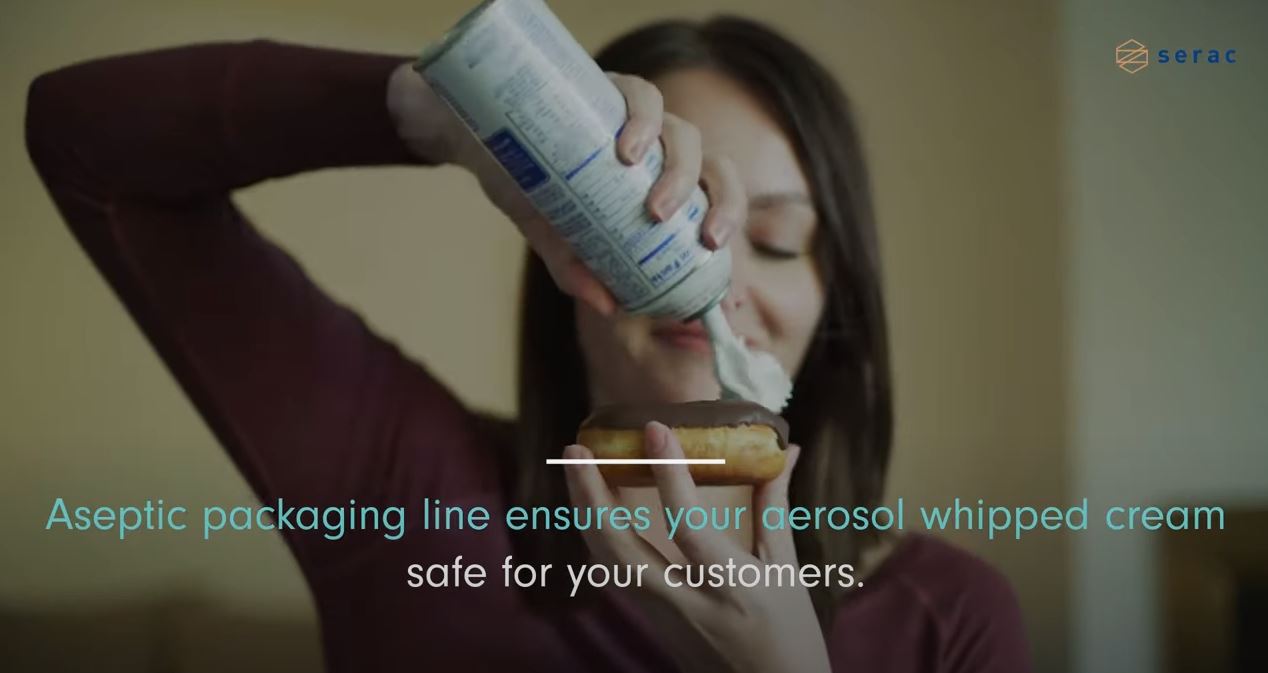

40 years of experience in aseptic filling

Dairy Products Filling Machines

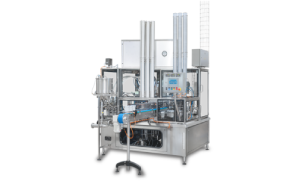

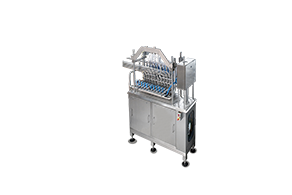

Over the last 50 years, Serac has gained a unique and very high level of expertise in the design and manufacture of packaging machines for dairy products in bottles or cups.

Some dairy products processed on our machines :

White milks, Flavored milks, enriched milks, drinking yogurts, fermented milks, liquid cream, cheese, sour cream, spoonable yogurts, desserts cream, fresh or cooked dairy desserts.