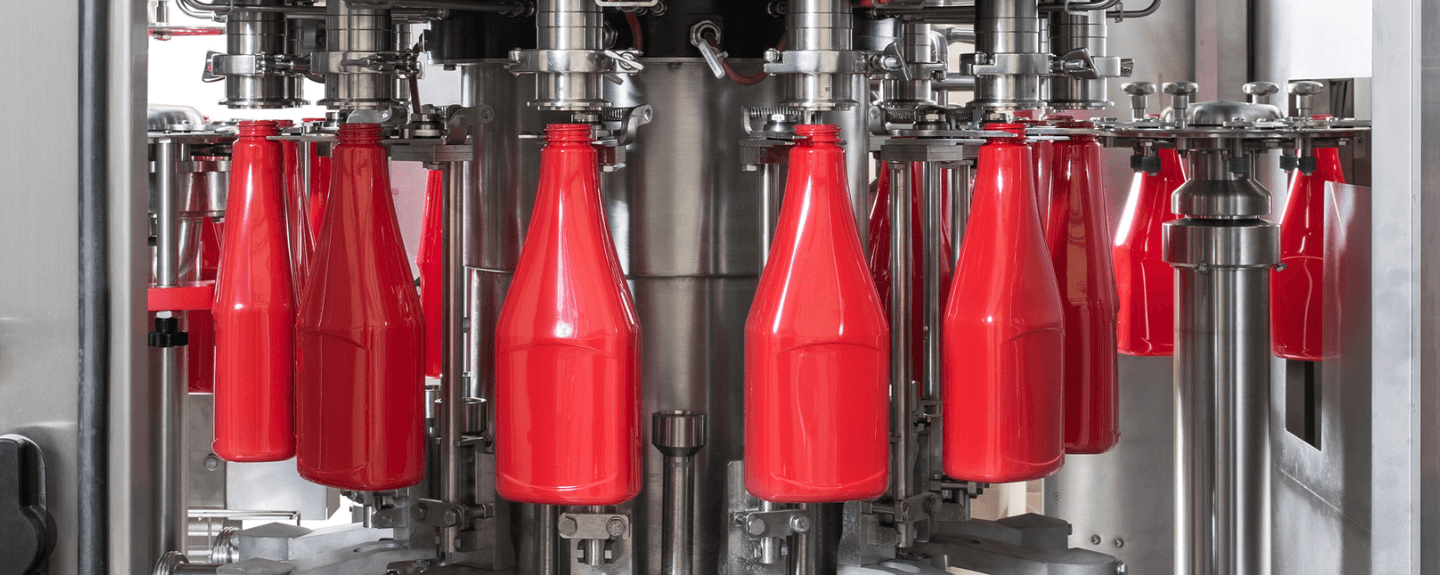

Serac Rotary Net Weight Filling Technology

Key Benefits:

More…

- Simple product circuit: low maintenance, fast change product to product and cleaning in place.

- Pass multiple products from foamy to viscous on the same machine and possibly without change-over on the product circuit.

- Produce and pack more bottles each day, up to 36,000 bottles per hour

- Overpressure filling for highly viscous product can be turn on and off depending on the recipe.

- Highly flexible with different bottle shapes and one machine can produce a range of up to 20 times the smallest size. (e.g. from 6.4 fl oz to 1 gallon or 128 fl oz)

Highly Accurate Filling

For a 1000g bottle, Serac commits on sigma = 1 gram.

This means that all the bottles will be between 997g and 1003g (6 sigma).

- Insensitive to temperature

- Insensitive to aeration

- Filling with permanent control of the closing point

- Complete production report, accuracy and efficiency tracking

Hygienic Design

Our filling/capping/sealing machines conform to 3-A Sanitary Standards (USA).

- No contact between nozzle and container, no retention

- Simple Product Circuit

- Clean-In-Place Facilities

- No Dynamic Seals nor Piston/Membranes

Product types:

- Ketchups, BBQ sauces, Mayonnaise, Mustard, Soy Sauce, etc.

- Pasta sauces, Pesto, Alfredo, etc.

- Chunky Salsa, Taco Sauces, etc.

- Ranch Dressings, Balsamic Vinaigrette, Caesar Salad, etc

Size Range

- 7 Fluid Oz to 5 Gallons

Recipes & processing

- Foamy, viscous, with particles

- Low acid, high acid

- Hot Fill, Cold fill, UHT

Materials

- PET/rPET, HDPE, PP, Glass, Aluminium

Shapes

- Round, rectangles, with handles, etc.

Bottling Equipment for Sauces and Dressings

The design of our filling and capping machines are dependant of the specificities of the sauces or dressings to be filled.

| Application | Examples | Distribution | Filler & Capper |

| Non Sensitive | Hot Filled Sauces, Vinegar, Soy Sauces, Chilli Sauces | Shelf-Stable | Clean |

| Semi Sensitive | Clean-label Ketchups, Regular Mayonnaise | Ambient | Ultra-Clean |

| Semi Sensitive | Fresh Sauces / Soups | Chilled | Ultra-Clean |

| Sensitive | Low-Fat Mayonnaise | Ambient | Aseptic |

Ultra-Clean Cold Filling for Sauces and Dressings

The sensitivity of the recipes will define the level of hygiene and packaging treatments. We offer packaging treatments such as de-dusting or decontamination prior to the filling:

| Treatments | Preform/Bottles/Jars | Caps (Closure) | Alu Foil | Cups |

| Filtered Air Dry | Yes | Yes | – | – |

| Pulsed Light Dry | – | Yes | Yes | Yes |

| Controlled H₂O₂ Dry | Yes | Yes | Yes | Yes |

Filling Machines for Liquid & Viscous Sauces and Dressings in North America

Serac Inc designs, engineers and builds machines in the USA. Our proximity is enhanced by our international presence & expertise, allowing us to offer unmatched services at the highest standards across the Americas.

Welcome to Serac Inc, where we make filling machines for sauces, dressings and other liquid and viscous food products

Our factory in Carol Stream, IL is open for Visits.

Come and see how we will assemble and test your future filler and capper!

Contact us to book a visit:

160 E Elk Trail, Carol Stream, IL 60188